Forged Screwed-Threaded Hex Nipple Supplier & Manufacturer

A Forged Screwed-Threaded Hex Nipple is a type of pipe fitting threaded on both ends with a hexagonal shape in the middle. It is forged using high-quality materials to ensure maximum strength and durability. The hexagonal shape allows easy installation and removal using a standard wrench, making it a popular choice for many piping applications. The Forged Screwed-Threaded Hex Nipple. is commonly used to connect two pipes or fittings with female threads. It is designed to create a tight and secure seal between the two components, preventing any leaks or damage to the surrounding area. This type of fitting is often used in high-pressure applications such as oil and gas, chemical processing, and power generation plants. The Forged Screwed-Threaded Hex Nipple comes in various sizes and materials, including carbon steel, stainless steel, brass, and others. Its threaded ends allow easy installation without additional equipment or complicated procedures, making it a versatile and practical option for many industrial applications.

The forged screwed threaded hex nipple is widely used in the piping industry as these small plumbing subsets create a great change in the piping system. There are different types of nipple available, and forged screwed threaded nipple is considered great as they do not require any extra strength. The hex nipple is known best for its excellent features and properties. The features include high tensile strength, durability, formability, workability, and long service life.

ASTM A 182 Stainless Steel Forged Threaded Hex Nipple, Hex Nipples, Hex Nipples Suppliers, Hex Nipples Exporters, Hex Nipples Manufacturers, Forged Screwed-threaded Hex Nipple, Alloy Steel Forged Screwed Hex Nipple, Screwed Hex Nipple, Forged Hex Nipple, ASME / ANSI B 16.11 Duplex Steel Screwed Hex Nipple Supplier & Exporter.

When used in the piping system, these fitting components can create a great change and help the piping system to bear high pressure easily. However, when you want to spare a small space between the threaded ends, it is best to use a hex nipple with a hexagonal section in the middle. The equipment works like a nut, easily gripped by a normal wrench, offering greater mechanical benefit than the normal round pipes. The hex nipple having more distance between the threaded ends is known as the long hex nipple.

The manufacturers manufacture these Forged Screwed-Threaded Hex Nipple using top-notch and international quality standard raw material that qualified professionals will inspect. Before sending it for the manufacturing process, every material is tested to provide its best under the respective areas of working. The hex nipple is made considering the pipe's size and requirements of a diverse range of applications.

SS Threaded Hex Nipple, Carbon Steel Forged Screwed Hex Nipple, Hex Nipples Stockists, Hex Nipples Suppliers Dealers, Threaded Forged Hex Nipple, Forged Threaded Hex Nipple, Threaded Hex Nipple, ASME B16.11 Threaded Hex Nipple, Threaded Reducing Hex Nipple, Forged Threaded Hex Nipple, Alloy Steel Threaded Hex Nipple Fittings Manufacturer.

These fittings components are well inspected and tested by the inspection agencies to check whether the material is made as per customers' demand and by the rules of the industry or not.

Hence, you can buy different types and forms of screwed-threaded hex nipples online at competitive rates.

We supply a wide range of high-quality Threaded Hex Nipples. Ex-Head Bushings is a type of pipe fitting defined as a part used in a piping system. Welding a fitting to the pipe means it is permanently leakproof. We also customize Threaded Hex Nipples our range as per the specifications laid down by our clients.

Hex nipples are available in the industry's widest variety of wall thicknesses and materials. Our nipples are tested and verified for durability, accuracy and precision.

What is a Forged Screwed-Threaded Hex Nipple?

A Forged Screwed-Threaded Hex Nipple is a type of pipe fitting that is used to connect two pipes or hoses together. It has a hexagonal shape on one end & threads on the other end, which allows it to be screwed onto another piece of pipe or hose.

What are the Benefits of Forged Screwed-Threaded Hex Nipple?

Screwed Hex Nipple provides a secure and reliable connection between pipes or hoses. They are easy to install and can be tightened using a wrench. They are available in a variety of materials, including carbon steel, stainless steel, and brass, which makes them suitable for use in a wide range of applications. They have a hexagonal shape on one end, which provides a better grip for tightening and loosening.

What are the common applications of Forged Screwed-Threaded Hex Nipples?

Forged Screwed Threaded Hex Nipple are commonly used in a wide range of industrial & commercial applications including plumbing, heating, & air conditioning.

Materials and Grade :

| Specification | : | ASTM A182, ASTM SA182 |

| Dimension | : | ANSI B 16.11 / BS3799 |

| Size | : | 1/4" NB TO 4" NB |

| Class | : | 2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS |

| Range | : | Coupling, Plug, Socket, Bushing, Elbow, Tee, Nipple, Union,Threading Outlet, Welding Outlet, Sockt Weld Outlet. |

| Stainless Steel Screwed-Threaded Hex Nipple | : | ASTM A182 F304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L |

| Duplex Steel Screwed-Threaded Hex Nipple | : | ASTM A 182 –F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 S 31803, S 32205, S 32550, S 32750, S 32760 |

| Carbon Steel Screwed-Threaded Hex Nipple | : | ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2 |

| Alloy Steel Screwed-Threaded Hex Nipple | : | ASTM / ASME A 182 GR F 5, F 9, F 11, F 12, F 22, F 91. |

| Copper Alloys Screwed-Threaded Hex Nipple | : |

ASTM / ASME SB 111 UNS NO. C 10100 , C 10200 , C 10300 ,

C 10800 , C 12000, C 12200, C 70600 C 71500 ASTM / ASME SB 466 UNS NO. C 70600 ( CU -NI- 90/10) , C 71500 ( CU -NI- 70/30) |

| Nickel Alloy Screwed-Threaded Hex Nipple | : | ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200) , UNS 2201 (NICKEL 201 ) , UNS 4400 (MONEL 400 ) , UNS 8020 ( ALLOY 20 / 20 CB 3 ) , UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600 ) , UNS 6601 (INCONEL 601) , UNS 6625 (INCONEL 625) , UNS 10276 (HASTELLOY C 276) |

Forged Screwed-Threaded Hex Nipple Price List

| S.NO | Description | Piping Material Class | Qty | PRICE IN US($) |

| 1. | HEX NIPPLE: 2NPS X 1/2 NPS, ECC.TYPE, ASTM A234-WPB, SMLS,BE X PE, SCH80XSCH80, NACE MR-0175/ ISO 15156 ,BS 3799 | A01E | 6 NOS | $72.00 |

| 2. | HEX NIPPLE: 2NPS X 1 NPS, CONC.TYPE, ASTM A234-WPB, SMLS, BE X PE, SCH80XSCH160, NACE MR-0175/ ISO 15156, BS 3799 | A03E | 5 NOS | $82.00 |

| 3. | HEX NIPPLE: 2NPS X 1 NPS, CONC.TYPE, ASTM A234-WPB, SMLS, BE X PE, SCH80XSCH80, NACE MR-0175/ ISO 15156, BS 3799 | A01E | 5 NOS | $92.00 |

| 4. | HEX NIPPLE: 2NPS X 1-1/2 NPS, ECC.TYPE, ASTM A234-WPB, SMLS, BE X PE, SCH80XSCH80, NACE MR-0175/ ISO 15156, BS 3799 | A01E | 6 NOS | $82.00 |

Forged Screwed-Threaded Hex Nipple Pressure Rating

| ASME B16.11 Hex Nipple Temperature | |||||

|---|---|---|---|---|---|

| Temperature | Class | ||||

| 150 | 300 | ||||

| 1/4 - 1 inches | 1 1/4 - 2 inches | 2 1/2 - 3 inches | |||

| (oF) | (oC) | ||||

| -20 to 150 | -29 to 66 | 300 | 2000 | 1500 | 1000 |

| 200 | 93 | 265 | 1785 | 1350 | 910 |

| 250 | 121 | 225 | 1575 | 1200 | 825 |

| 300 | 149 | 185 | 1360 | 1050 | 735 |

| 350 | 177 | 150 | 1150 | 900 | 650 |

| 400 | 204 | - | 935 | 750 | 560 |

| 450 | 232 | - | 725 | 600 | 475 |

| 500 | 260 | - | 510 | 450 | 385 |

| 550 | 288 | - | 300 | 300 | 300 |

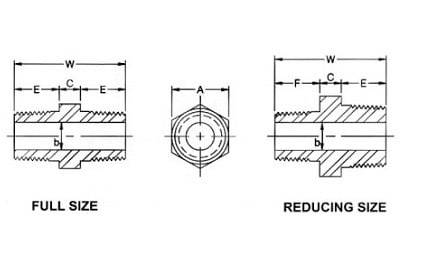

Forged Screwed-Threaded Hex Nipple Tolerance

| ANSI B16.11 American Standard Dimensional Tolerances | ||

|---|---|---|

| "A" - Threaded Center To Bottom |

For Size 1/8" And 1/4" |

± 0.03" |

| 3/8", 1/2" And 3/4" | ± 0.06" | |

| 1", 1-1/4", 1-1/2" And 2" | ± 0.08" | |

| 2-1/2", 3", And 4" | ± 0.10" | |

| "B" - Threaded Bore Diameter |

For Size 1-1/2" And Smaller |

+ 0.020" - 0.000" |

| 2", 2-1/2", 3" And 4" | + 0.025" - 0.000" |

|

| "C" - Threaded Wall Thick. |

Min. = 1.09 T (But Not Less Than 5/32") T = Wall Thickness Of Nominal Pipe Sizes |

|

| "D" - Bore Diameter Of Pipe Fitting |

For Size 2" And Smaller |

± 0.030" |

| 2-1/2", 3" And 4" | ± 0.060" | |

| "E" - Threadeds- Bottom To Bottom - Full Couplings |

For Size 1/8" And 1/4" |

± 0.06" |

| 3/8", 1/2" And 3/4" | ± 0.12" | |

| 1", 1-1/4", 1-1/2" And 2" | ± 0.16" | |

| 2-1/2", 3", And 4" | ± 0.20" | |

| "F" - Bottom Of Threaded To Opposite Face - ANSI B16.11 Half Couplings |

For Size 1/8" And 1/4" |

± 0.03" |

| 3/8", 1/2" And 3/4" | ± 0.06" | |

| 1", 1-1/4", 1-1/2" And 2" | ± 0.08" | |

| 2-1/2", 3", And 4" | ± 0.10" | |

| "G" - Gap Of Welding |

Approx. 0.06" Before Welding Recommended Gap |

|

| "H" - Min. Flat |

Min. Flat = 0.75 X Min. Threaded Wall Thick. |

|

Forged Screwed-Threaded Hex Nipple Weight Chart

| NPS |

Minimum Length A |

Nominal Head Diameter D |

Minimum Length E |

| 1/2 | 44 | 21 | 14 |

| 3/4 | 44 | 27 | 16 |

| 1 | 51 | 33 | 19 |

| 1¼ | 51 | 43 | 21 |

| 1½ | 51 | 48 | 21 |

| 2 | 64 | 60 | 22 |

| 2½ | 70 | 73 | 37 |

| 3 | 70 | 89 | 28 |

| 4 | 76 | 114 | 32 |

Forged Screwed-Threaded Hex Nipple Dimensions

|

| Nominal Diameter |

Outside Diameter D |

L(mm) | |

| DN | NPS | ||

| 8 | 1/4 | 13.5 |

60 90 120 150 180 |

| 10 | 3/8 | 17.2 | |

| 15 | 1/2 | 21.3 | |

| 20 | 3/4 | 26.7 | |

| 25 | 1 | 33.4 | |

| 32 | 1.1/4 | 42.2 | |

| 40 | 1.1/2 | 48.3 | |

| 50 | 2 | 60.3 | |

Types of Forged Screwed/Threaded Hex Nipple :

| » | Forged Screwed / Threaded Hex Nipple |

| » | Stainless Steel Threaded Hex Nipple Exporter |

| » | Duplex Steel Forged Screwed Hex Nipple |

| » | Carbon Steel Forged Threaded Hex Nipple |

| » | Alloy Steel Screwed Hex Nipple Supplier |

| » | Super Duplex Steel Threaded Hex Nipple |

| » | Copper Alloy Steel Screwed Hex Nipple |

| » | Nickel Alloy Forged Threaded Hex Nipple |

| » | Monel Forged Screwed Hex Nipple Dealer |

| » | SS A182 Class 6000 Threaded Hex Nipple |

| » | ASME B16.11 Forged Screwed Hex Nipple |

| » | Hastelloy Forged Threaded Hex Nipple |

| » | Inconel Screwed Hex Nipple Distributor |

| » | Titanium Forged Threaded Hex Nipple |

| » | Incoloy Screwed Hex Nipple Manufacturer |

| » | SS ANSI B16.11 Forged Threaded Hex Nipple |

| » | BS3799 Forged Screwed Hex Nipple Stockiest |

| » | Class 3000 Lbs SS Forged Threaded Hex Nipple |

| » | SS ASTM A182 Forged Screwed Hex Nipple |

| » | Class 2000 Lbs Threaded Hex Nipple Exporter |

- Socket Weld Fittings

- Screwed-Threaded Fittings

- Forged 90 Deg Screwed-Threaded Elbow

- Forged 45 Deg Screwed-Threaded Elbow

- Forged Screwed-Threaded Equal Tee

- Forged Screwed-Threaded Unequal Tee

- Forged Screwed-Threaded Equal Cross

- Forged Screwed-Threaded Unequal Cross

- Forged Screwed-Threaded Half coupling

- Forged Screwed-Threaded Full coupling

- Forged Screwed-Threaded Cap

- Forged Screwed-Threaded Plug

- Forged Screwed-Threaded Bushing

- Forged Screwed-Threaded Hex Nipples

- Street Elbows

- Welding Boss

- Union BS 3799

- Swage Nipple

- Stainless Steel Forged Fittings

- Duplex Steel Forged Fittings

- Carbon Steel Forged Fittings

- Alloy Steel Forged Fittings

- Copper Nickel Forged Fittings

- SMO 254 Forged Fittings

- Alloy 20 Forged Fittings

- Hastelloy Forged Fittings

- Inconel Forged Fittings

- Monel Forged Fittings

- Titanium Forged Fittings

- Buttweld Fittings

- Flanges

- Pipes Tubes